Glove boxes are made of heavy duty stainless steel structure glove box with vacuum covers on glove port, which allow you to reach high vacuum (10-2 torr) before filling inert gas and save time and gas for chamber purging It is excellent glove-box at lower cost for a wide range of researching processes in material science, chemistry, semiconductor and related industries.

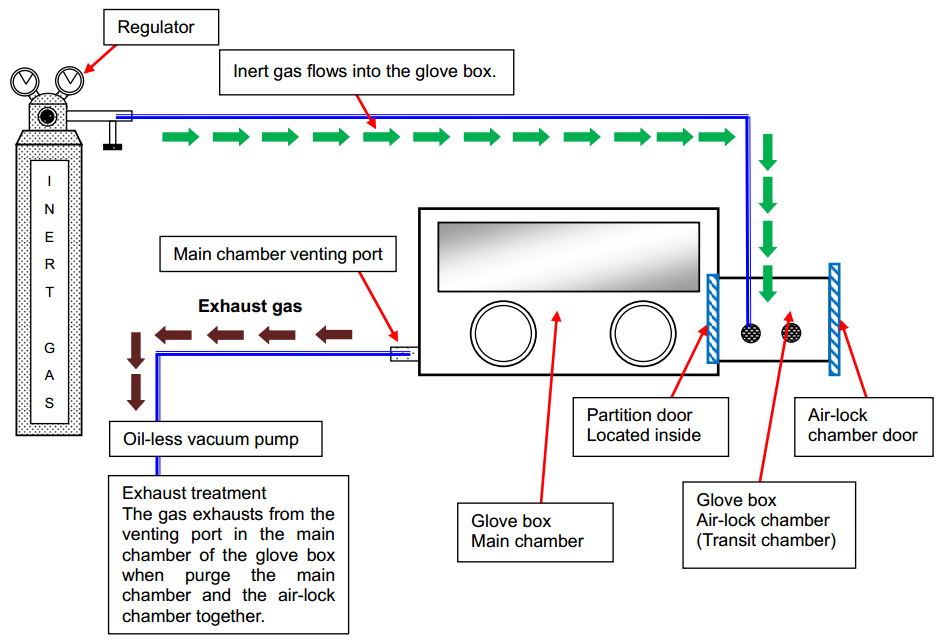

STRUCTURE (step 1)

1) Connect the inert gas supply, vacuum pump and glove box in the form which is showing in the figure above.

2)Open the partition door (which is located between the main chamber and the air-lock chamber).

3) Close the air-lock chamber door.

4) Open the release valve for gloves. Turn on the pump and open its corresponding valve.

5) Observe the vacuum gauge in the glove box. When the pressure is approaching -0.1Mpa, close the valve and turn off the vacuum pump.

6) Open the valve in the gas supply and adjust the regulator to set the flow gas pressure to ≤0.5Mpa. (If possible please connect an additional flow meter to the inlet of the gas purifying units. Adjust the flow meter to set the flow rate to ≤10L/min)

7) Open the gas inlet valve in the glove box. Now the inert gas is inserting into the glove box.

8) Observe the pressure gauge. When the pressure inside returns to the atmosphere pressure. Close the gas inlet valve. The valve in the gas supply can be open.

9) Repeat from the step 2 to step 7 until the O2and H2O content inside the glove meets the processing requirement. (It may be vary depending on the purity of the inert gas. Recommend using 99.999% purity inert gas.)

10) Make the pressure inside the glove box return to atmosphere pressure.

11) Close the release valve for gloves.

12) Wear the gloves to close the partition door

Step 2. Purge the air-lock when loading the samples.

The step 2 need be done each time when loading the sample into the main chamber.

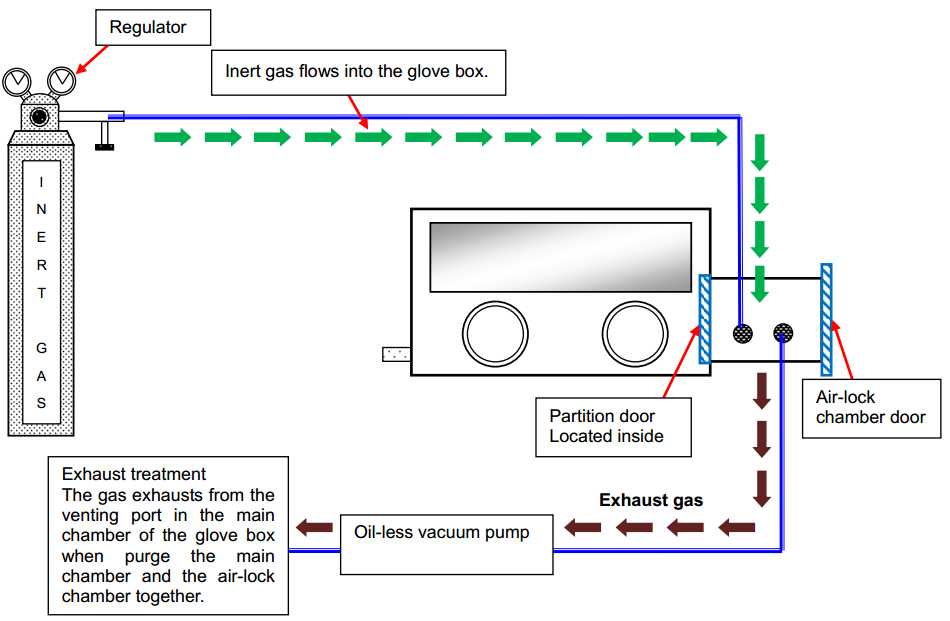

STRUCTURE (step 2)

1) Make sure the pressure inside the glove is atmosphere pressure.

2) Wear the gloves to close the partition door.

3) Connect the inert gas supply, vacuum pump and glove in the form which is showing in the figure above.

4) Open the air-lock chamber door.

5) Place the sample inside the air-lock chamber.

6) Close the air-lock chamber door.

7) Connect the pump to the air-lock chamber and do vacuuming.

8) Observe the pressure gauge when it points at the -0.1Mpa close the valve (and turn off the vacuum pump).

9) Open the gas supply and insert the inert gas from the other valve of the air-lock chamber.

10) Close the valve when the pressure inside the air-lock chamber returns to atmosphere pressure.

11) Repeat the step 7) to 10) several times. Finally make the pressure inside the air-lock chamber to be atmosphere pressure.

12) Wear the gloves to open the partition door.

13) Take the samples into the main chamber.

14) Close the partition door.

15) Loading finished.

Note

I. It is impossible to operate under vacuum status.

II. Please always make the pressure inside the glove box return to atmosphere pressure before opening the release valve for gloves.

III. If the glove box is leaking somewhere

a. Please check the air-lock chamber door whether has been tighten enough.

b. Then check the o-ring of the air-lock chamber door and the partition door and replace the damaged o-ring.

c. Check the joint of the valves and pressure gauge. Apply some vacuum grease at the joints.

IV. If the gloves keep inflating during vacuuming.

a. First make sure the release valve for the gloves is open completely.

b. If the gloves still being inflating please turn off the vacuum pump immediately.

c. Check the glove flanges whether are tighten enough.

d. Check the o-ring installed in the glove flanges.

e. Check the pipe connecting between release valve and glove flanges.